Leveraging AWS and Azure Solutions to Tackle Supply Chain Challenges in Car Manufacturing.

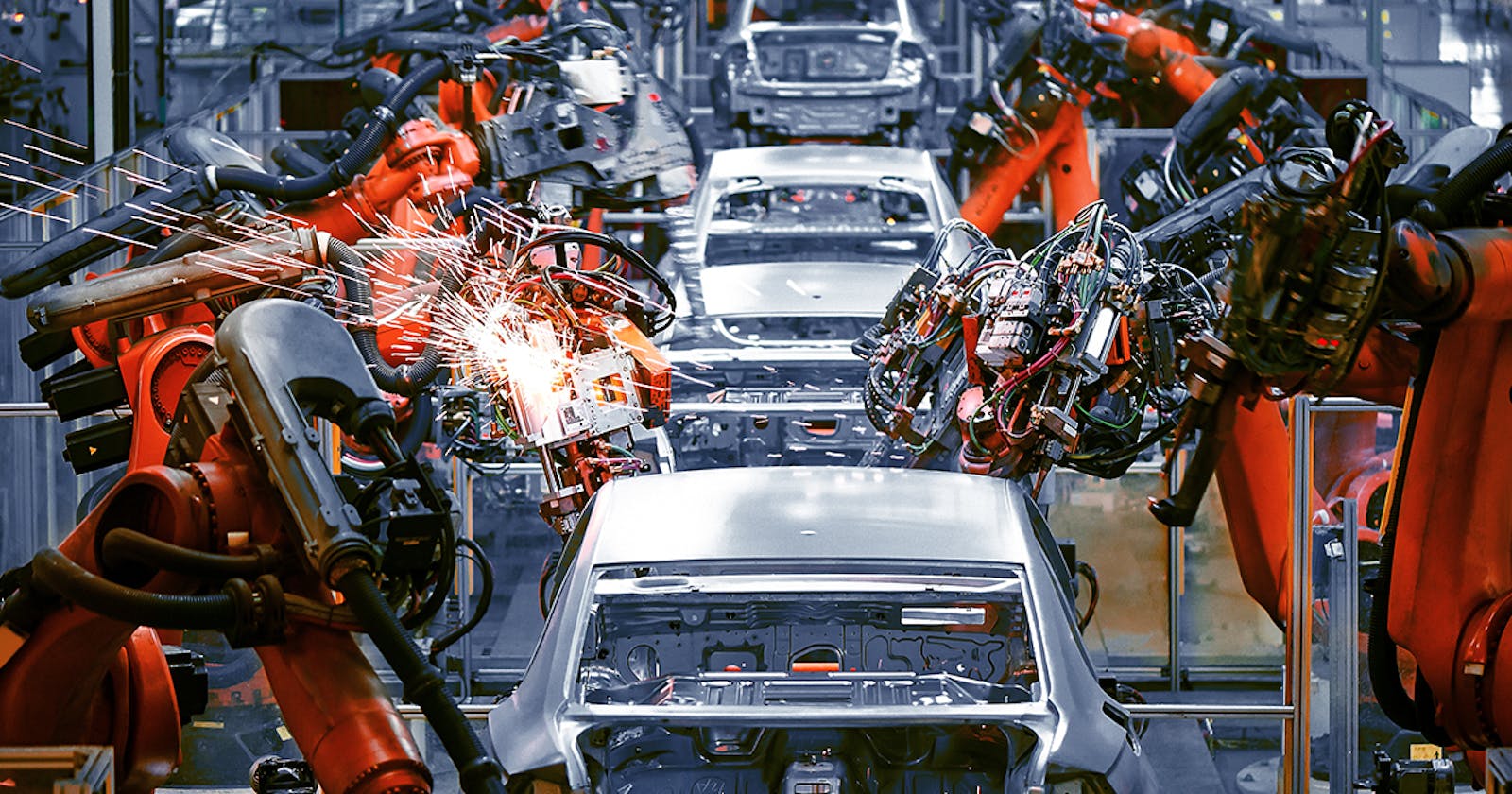

The car manufacturing industry is highly complex, with numerous challenges related to supply chain management. Timely and efficient delivery of parts and components is crucial to ensure smooth production processes and meet customer demands. To address these challenges, car manufacturers are turning to cloud computing services, specifically AWS (Amazon Web Services) and Azure (Microsoft Azure), to optimize their supply chain operations. As a multi-cloud solution architect, let's explore how the car manufacturing industry can leverage AWS and Azure services to overcome supply chain challenges.

Supply Chain Challenges in Car Manufacturing:

1. Inventory Management: Car manufacturers must manage a vast range of parts and components from various suppliers. Maintaining optimal inventory levels and minimizing stockouts is essential.

2. Demand Forecasting: Accurate demand forecasting is crucial to optimize production planning, reduce inventory costs, and avoid overstocking or stockouts.

3. Supplier Collaboration: Collaborating effectively with suppliers to ensure on-time delivery, quality control, and adherence to production schedules is a critical aspect of supply chain management.

4. Logistics and Transportation: Managing transportation, tracking shipments, and optimizing routes to ensure timely delivery while minimizing costs is a significant challenge.

5. Data Integration: Consolidating data from multiple systems and sources to gain real-time visibility into supply chain operations is essential for efficient decision-making.

Leveraging AWS and Azure Services:

1. Inventory Management:

- AWS Service: Amazon Simple Storage Service (S3) provides secure, scalable, and highly available object storage for storing inventory data.

- Azure Service: Azure Blob Storage offers cost-effective, scalable storage for storing inventory data.

2. Demand Forecasting:

- AWS Service: Amazon Forecast leverages machine learning algorithms to generate accurate demand forecasts based on historical data and external factors.

- Azure Service: Azure Machine Learning enables car manufacturers to build and deploy predictive models for demand forecasting.

3. Supplier Collaboration:

- AWS Service: Amazon API Gateway helps car manufacturers securely expose APIs to suppliers, enabling seamless communication and data exchange.

- Azure Service: Azure Logic Apps enables the creation of workflows and orchestrations to automate supplier collaboration processes.

4. Logistics and Transportation:

- AWS Service: Amazon Elastic Compute Cloud (EC2) provides scalable computing resources to optimize transportation route planning and manage logistics.

- Azure Service: Azure Maps offers location-based services and APIs for optimizing transportation routes and tracking shipments.

5. Data Integration:

- AWS Service: AWS Glue facilitates data integration by automatically discovering, cataloging, and transforming data from various sources for analysis.

- Azure Service: Azure Data Factory enables data integration and orchestration across various sources and destinations, ensuring data consistency.

Conclusion:

The car manufacturing industry faces numerous challenges in supply chain management. By leveraging the power of AWS and Azure services, car manufacturers can optimize inventory management, enhance demand forecasting accuracy, streamline supplier collaboration, optimize logistics and transportation, and integrate data from various sources. Adopting a multi-cloud approach with AWS and Azure can provide flexibility, scalability, and reliability to address the dynamic requirements of the car manufacturing supply chain. With these cloud-based solutions, car manufacturers can enhance operational efficiency, reduce costs, and meet customer demands more effectively.